WATER INRUSH CONTROL AT THE INTERFACE BETWEEN OFFSHORE BRIDGE

FOUNDATION PILES AND PIER STEEL BOX COFFERDAM

Water pressure balanced resin grouting water-stop reinforcement

―

1. Project Background

Some piers of a cross-sea bridge were designed with pier steel box cofferdam foundations. However, due to the prior construction of the offshore steel pipe piles, when the steel box cofferdam assembly work commenced, a large number of marine organisms had already attached themselves to the surface of the piles. This prevented the complete closure of the waterstop plate between the steel box and the piles. The steel box could potentially experience upward displacement due to tidal effects.

To ensure the stability of the steel box’s elevation, it became necessary to promptly pour a 1.5-meter-thick bottom seal concrete at the bottom of the steel box. However, due to the influence of tides and sea waves, the concrete’s hydration process encountered seawater intrusion, resulting in a high influx of water into the steel box at the sealing plate location, exceeding 5 cubic meters per minute.

This issue had a significant impact on subsequent procedures, such as concrete casting, rebar binding, and pile head treatment. To avoid project delays, the construction team decided to entrust a professional contractor with experience in water-stop reinforcement to conduct a method analysis. After the review was approved, they proceeded with the execution of the plan.

―

2. Solution

Due to the influence of tides, there was a continuous difference in water levels both inside and outside the steel box, resulting in the presence of flowing water within the concrete perforations. Additionally, the fluctuating sea waves exacerbated the flow rate and pressure variations within the holes.

To achieve the goal of sealing irregular holes in mass concrete under tidal conditions, the water-stop reinforcement plan was as follows:

1. Use fast-setting polyurethane resin with rapid gelling time, good adhesiveness, and flexibility after curing to fill the perforations and gaps.

2. Utilize pre-embedded pipeline injection.

3. Perform injection under water pressure equilibrium conditions to minimize the displacement of injected grout material within the holes.

4. Employ an angled drilling technique and a two-stage injection method with expanding and non-expanding resin grout material to ensure long-lasting hole sealing.

This to ensure that seawater no longer infiltrated during processes such as rebar binding, pile head treatment, concrete pouring, and curing.

―

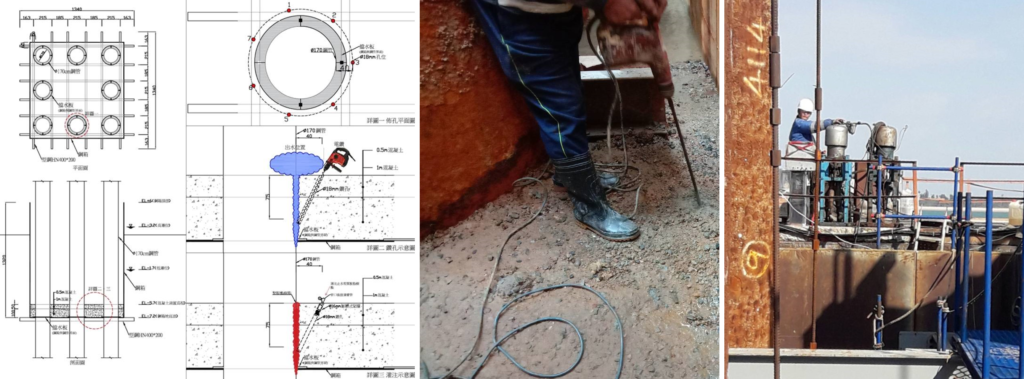

3. Works Design

Due to the numerous leakage points and a significant volume of water, in order to achieve water infiltration control as comprehensively as possible in a single attempt, the related works design was as follows:

1. Remove the accumulated water inside the steel box and mark the locations of water seepage during high tide periods.

2. Drill inclined holes around the marked locations, ensuring that the grout outlets are positioned as centrally as possible within the 1.5-meter thick bottom concrete.

3. Install 1.5-inch grouting pipes and connect them to mixers, high-pressure hoses, and other equipment at the hole openings.

4. Simultaneously set up a work platform at the top of the steel box or at an adjacent suitable location. Hang medium-flow resin grout pumps, pressure and flow controllers, diverters, and material storage tanks on the platform.

5. Install water pumps both inside and outside the steel box and control the water levels inside and outside to make them as consistent as possible.

6. Under water pressure equilibrium conditions, conduct pressure grouting, with grouting pressure controlled within the range of initial pressure +3500 kPa or less.

7. After grouting is completed, observe changes in the water level inside the steel box during low tide periods.

8. Pump out any accumulated water inside the steel box and observe whether any leakage points still exist during high tide periods.

9. Perform additional grouting and restore the work site.

―

4. Works Process

The water pressure-balanced resin grouting was a specially designed grouting technique for this project. While it could not guarantee the discovery of all leakage pathways before grouting, it was known that most of the leakage sources originate from the waterstop plate at the bottom of the steel box, with many perforations interconnected.

Therefore, during resin grouting, the goal is to completely fill these holes and adequately fill them around the waterstop plate, effectively achieving waterstop reinforcement. The works process, apart from controlling the water levels inside and outside the steel box and the challenging work of divers descending to observe the grouting situation at the box bottom, proceeded smoothly in all other aspects.

―

5. Results

Following the completion of resin grouting under water pressure equilibrium conditions, during the ebb tide, the water level inside the steel box did not decrease. Subsequently, after draining the accumulated water and undergoing several rounds of ebb and flow tide, there was no recurrence of seawater infiltration within the steel box. The construction team reported this, and upon inspection, it was confirmed that the project had met the requirements for further construction, successfully achieving the water infiltration control at the interface of the offshore bridge pile and pier steel box cofferdam.

―

・More Construction Result Sharing

Contact us:+886 2769-2355