SITE IMPROVEMENT TECHNOLOGY FOR TBM SHAFT HORIZONTAL GROUTING

The site improvement technology to avoid impact with shallow obstacles.

1. Project Background

The capital of Thailand, Bangkok, is located on a sedimentary plain with an average elevation of about 2m.

The Chao Phraya River runs through the urban area. It is often troubled by floods and heavy water accumulation in the streets during the rainy season.

In recent years, government departments have established the BMA Flood Protection Tunnel Project, using the TBM construction method to build a number of large drainage tunnels underground in Bangkok to relieve the frequent flooding.

Among them, the improvement operation and project progress of the TBM reaching the launching face on the Bueng Nong bon Drainage Project was seriously affected by the density of underground pipelines around the shield TBM arrival well, which could not be temporarily relocated.

—

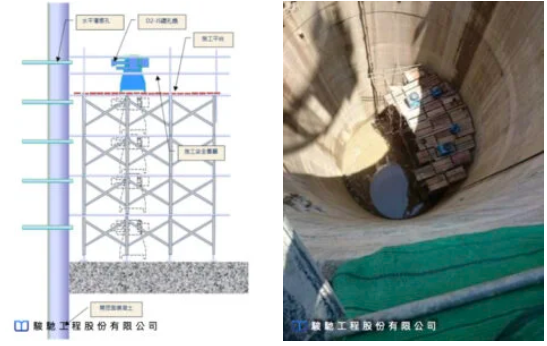

2. Solution

In order to solve the problem that the shallow pipelines could not be moved, the Administrator convened experts from all walks of life to discuss, and decided to first have the TBM dig a to reach the shaft, and then entrust an international professional contractor with rich experience in site improvement to carry out horizontal grouting in the shaft to reach the TBM and reinforce the stratum around the launching face and stop the water.

—

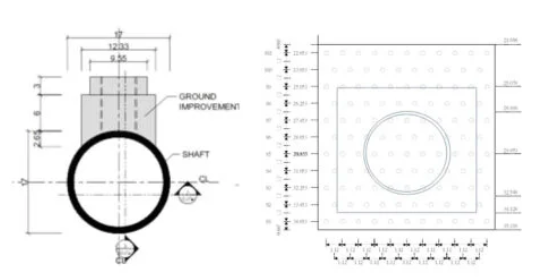

3. Works Design

The diameter of the TBM tunnel was about 5.5m, and the geological conditions for reaching the launching face were interbedded with clay, silt and fine sand.

In order to ensure the safety of the TBM while the face was broken, after careful analysis, it was decided to improve the proximal site of the 14m×12m×6m launching face and extend the reinforcement area of 9.55m×9.05m×3.0m. Cement-based and chemical-based grout to be used with double-tube horizontal reverse-stage composite grouting technology to ensure the stability of the formation and make the average formation permeability coefficient of the improved area not greater than 1×10-5cm/sec.

—

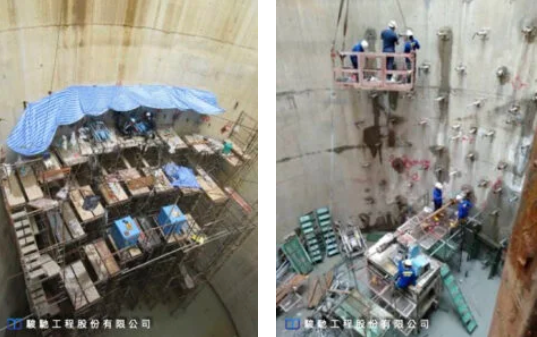

4.Works Process

The site block to be improved was mixed with sand layers, and the sand layers may have been connected to the Nong bon Lake water system in this block, so there was a layer with pressurized water.

A multi-stage construction method was adopted, and a large closed waterstop valve was installed first without penetrating the shaft structure.

Installation of all waterstop valves was completed, and after the water and sand gushing fully blocked during the drilling and pouring, Double Tube was used to drill through the sidewall structure of the shaft in order to carry out the horizontal inverse-stages grouting operation.

—

5. Results

After the grouting work was carried out according to the design, the monitoring results of the ground subsidence showed that the deformation of the ground and the pipeline was far less than the safe deformation.

After the launching face water permeability test, the permeability coefficient of the modified area was less than 1×10-5cm/sec.

Because the horizontal grouting technology and protective measures were well applied, there was no water or sand inrush during the tunnel face removal process. Impact of shallow obstacles was successfully avoided, and the horizontal grouting site in the TBM shaft was improved.

—

TBM Shaft Horizontal Grouting Site Improvement Technology

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd

1 Comment

Hi I am electrical engineer