GROUTING : SLOPING SITE BUILDING RAFT FOUNDATION WATER INRUSH HOT BITUMEN REPAIR TECHNOLOGY

The Technology for Serious Water Leakage in Foundation Slab and Side Walls of Building on Sloping site.

1. Project Background

There were two high-rise SRC buildings in a large-scale hillside development project. Four basements were fully excavated, and the foundation was situated on highly permeable rocky stratum.

During construction, due to the high water level at the rocky stratum under the foundation and the upper slope, the base water pressure was greater than 150kPa, and a large amount of water inrush (about 58m3/day) occurred at the raft base slab.

Groundwater even leaked into the basement of B4 floor through the steel structure column and concrete connection surface, which seriously affected the safety and function.

―

2. Soltuion

In order to take into account, the quality of the project, the developers specially convened well-known experts and construction companies at home and abroad to discuss countermeasures and conduct on-site trials.

Due to the large pores of the rocky stratum under the foundation and the groundwater flow on the hillside, it was not easy to form cement-based quick-setting grout.

In the end, the hot bitumen injection method was selected for raft foundation treatment as having the best leak-stop effect and would not be washed away by the inrush water.

―

3. Works Design

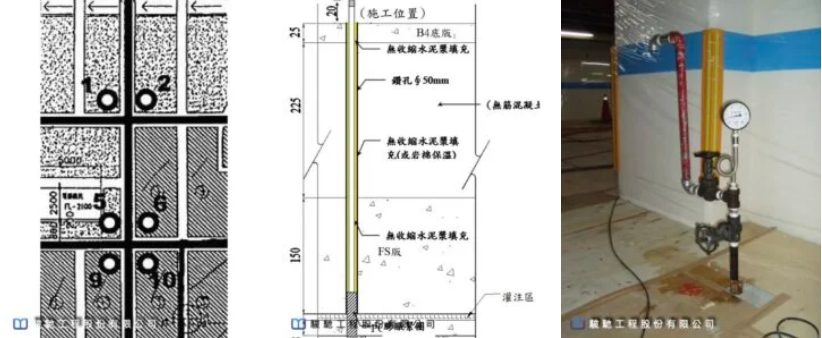

The location of the defect in the raft base slab was uncertain, and the accumulation of water in the water tanks made it difficult to perform non-destructive testing. The company specially developed a compressed air detection method, which used observation of the location and scale of water inrush and the emergence of bubbles to define the fractured area.

After inspection, it was found that the inrush channel was mainly concentrated at the column pile and foundation slab contact positions.In the design, in order to overcome the partitioning of the foundation slab by the sewage tank, the fire-fighting water tank and the elevator shaft, the cross-beam staggered hot bitumen grouting method was specially adopted.

The method of skip hole grouting and overflow hole reverse grouting ensures that the gaps in the concrete and rocky layer covered by the column piles are completely filled with hot asphalt.

―

4. Works Process

When a large amount of water inrush occurred in this building project, the basement structure had almost been completed, so the working space was extremely limited.

Under the conditions of not damaging the main structure and having to work in the water tank, our company specially made all equipment miniaturized and modularized to meet operational requirements.

During the works, first a small perforator was used to carry out the lead holes of the concrete base plate and the basement floor plate, and to install the water stop valve and outer casing pipe.

Next the hot bitumen grouting pipe, equipped with a plug was inserted into the casing, and the grouting operation was carried out per design procedure.

―

5. Results

After each column base in the foundation was grouted with hot bitumen, the water leaking along the column position to the basement stopped immediately.

After the grouting of all holes was completed according to the design, the water inrush stopped completely.Only small-scale water seepage existed around the function tanks that could not be entered for grouting.

After long-term observation, the repaired raft base slab seepage rate (<3m3/day) was much lower than the original design pump load capacity and contract requirements, and the raft slab inrush repair work had been successfully achieved.

―

Sloping Site Building Raft Foundation Water inrush Hot bitumen Repair Technology

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd