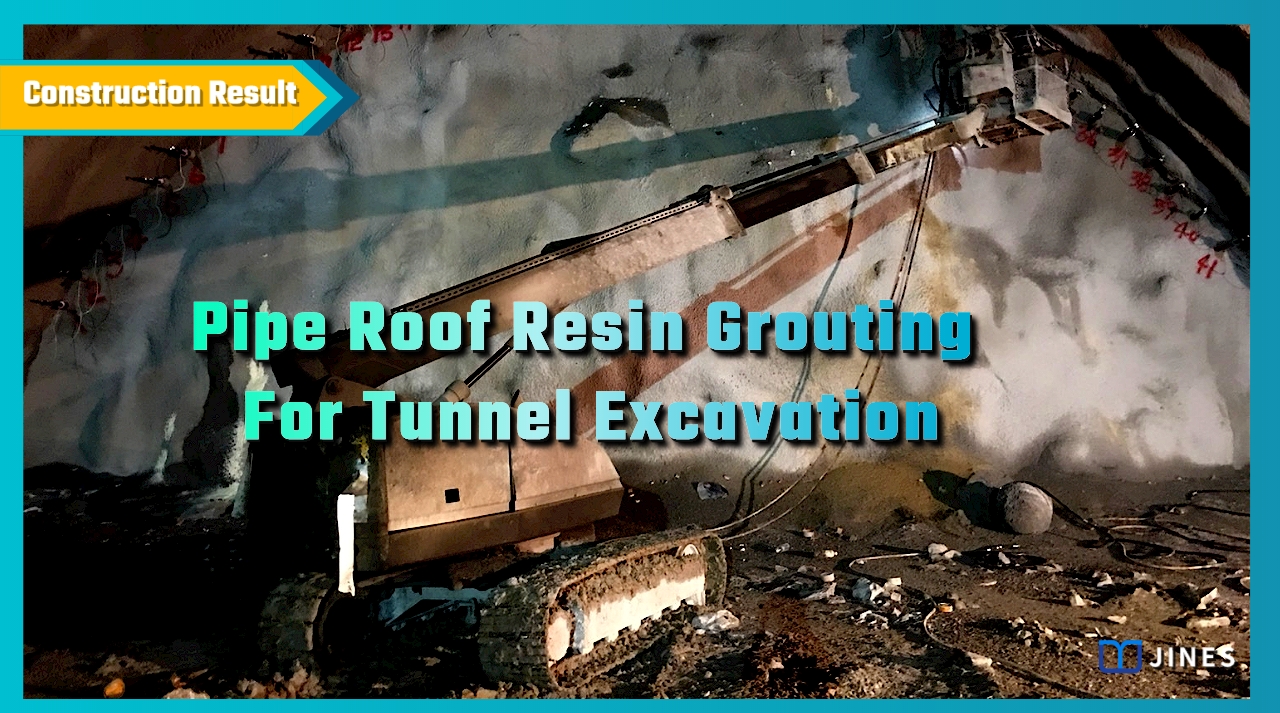

PIPE ROOF RESIN GROUTING FOR TUNNEL EXCAVATION

Rapid pre-Support pipe roof grouting reinforcement technology

1. Prokect Background

At a tunnel entrance there was a poorly cemented colluvial rock block layer about 27m long.

In order to prevent the damage of rock collapse during excavation and improve the progress of the project, the construction unit planned to use steel pipe roofing system as the forward longitudinal support outside the excavation zone.

The purpose was to stabilize the top arch of the excavation face and reduce any risk to subsequent construction.

―

2. Solution

In order to quickly stabilize the arch top of the excavation surface, the following solutions were formulated:

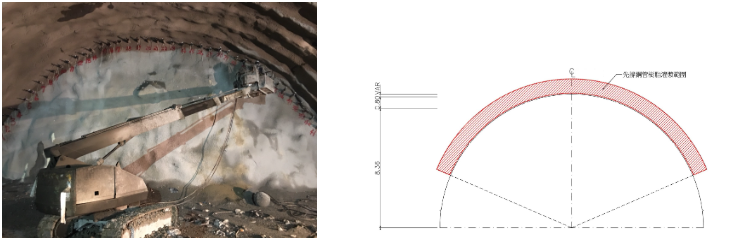

(1) Using an improved drill rig with a special drilling bit, a horizontal hole to be drilled along the outside of the tunnel excavation face;

(2) Using steel pipe inserted into the horizontal drilled holes to form the arch top pipe roof;

(3) Use polyurethane resin with fast curing time as the grouting material to reduce curing time;

(4) Using retarded resin with fixed flow rate and final pressure control method, the resin grout material can spread widely in the rock layer.

―

3. Work Design

Because the length of the colluvial rock blocks in the tunnel entrance section was about 27m, in order to fully consolidate the arch top, the works design was as follows:

(1) Pipe roof construction to be carried out in three stages; drilling lengths to be 15m, 15m and 12m respectively;

(2) At each stage, set @ 50cm along the outer edge of the excavation face, with a diameter of 4” drilling a total of 41 holes;

(3) A 10cm diameter open hollow steel pipe is to be placed in each drill hole;

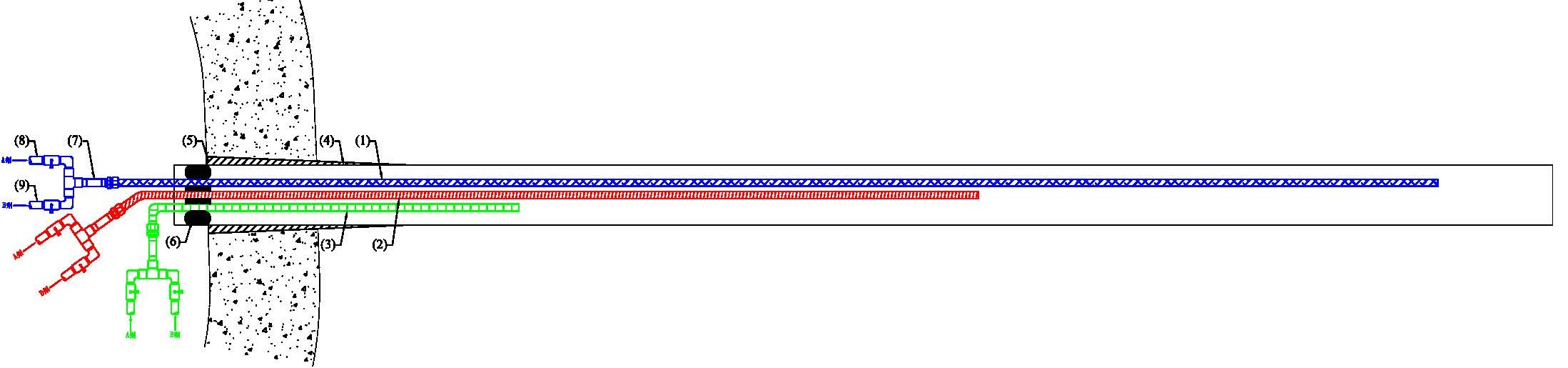

(4) Group of three grouting pipes to be inserted into the steel pipe. The grout outlets to be located at positions 12m, 9m, and 3m away from the opening;

(5) The nozzle and opening to be blocked with quick-setting cement to prevent back-flow grout;

(6) The grouting pipe opening to be connected to a static stirring rod, and connected to a medium-flow double-fluid grouting pump and monitoring system respectively by means of 1.5-diameter channel;

(7) Groups of three grouting pipes to be poured at the same time, the grout flow rate to be 10~15 liters per minute, and the maximum final pressure to be less than 5000kPa;

(8) Use 60-second reaction micro-expansion retarded polyurethane resin for grouting, the designed effective infusion radius is more than 30cm, and the overlapping range of the grout is at least 5cm.

―

4. Works Process

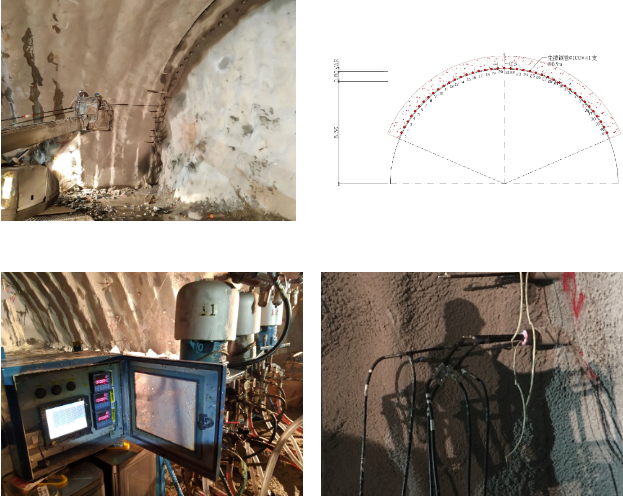

Due to the use of polyurethane resin as the grouting material, the equipment was mobilized quickly. The retarded grout starts to gel in about 60 seconds, and can cure in 90 seconds.

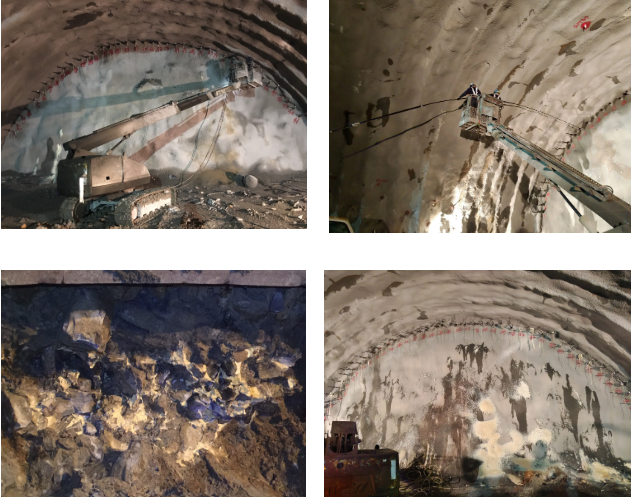

Equipped with an improved drilling rig, special drill bits, pre-assembled grouting pipes, etc., the drilling and filling time of each stage of pipe roofing was only 2 days. Coupled with the excellent filling and cohesion of the resin material rock layer, the excavation process was smooth.

It only took about 8 days to excavate every 15m colluvial rock block layer, which greatly shortened the construction time.

―

5. Results

This project was personally supervised by Mr. Shoji Sakai, an expert in the grouting industry. An automatic pressure and flow monitoring system was utilized for real-time observation. The grouting effectiveness was good, and the phenomenon of overflow of the grout rarely occurred.

Because the micro-expansion retarded polyurethane resin had a good effect on the infiltration, cementation and curing of the cracks of the rocks, the 27m colluvial rocky block layer was excavated and only took about 5 weeks.

The tunnel pipe roof resin grouting and excavation work were successfully completed.

―

PIPE ROOF RESIN GROUTING FOR TUNNEL EXCAVATION

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd