GROUTING IMPROVEMENT TECHNOLOGY TO PROTECT CLOSE PROXIMITY GROUND STRUCTURE

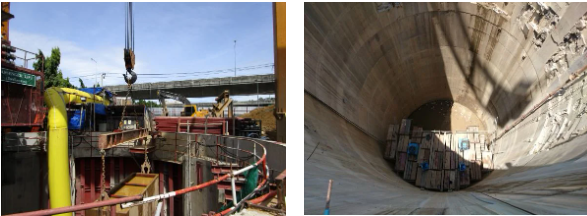

Protection of vertical shaft caisson construction adjacent to unerground tunnel

1.Project Background

Grouting Improvement : Bangkok, Thailand’s capital, is extremely waterlogged during the rainy season.In recent years, the BMA Flood Protection Tunnel Project had been constantly promoting the building of large underground drainage tunnels in Bangkok to relieve flooding during the rainy season.

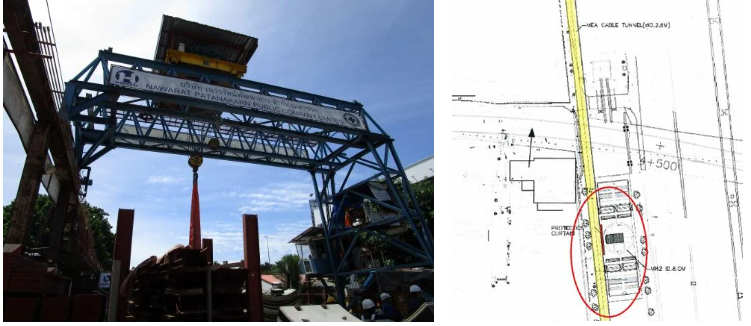

Among them, the vertical shaft TBM tunnel was to be only about 0.68m away from an existing large-scale MEA cable tunnel.In order to prevent deformation and damage of the cable tunnel during the construction of the vertical shaft, experts in the industry were specially entrusted to jointly develop protective measures.

―

2. Solution

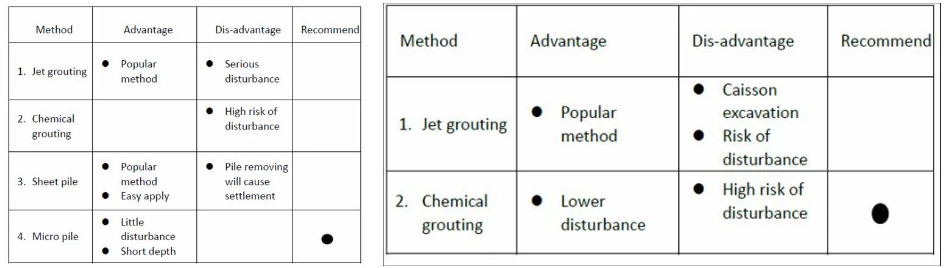

Traditional stratum excavation protection measures often use cement-based high-pressure jet-grout piles to improve localized ground areas.The strength of cement-soil mixture after solidification reduces the active earth pressure and lateral deformation of the ground formation.

However, because the ground improvement area was close to an existing tunnel, and the vertical shaft was to be constructed by the caisson method, the high-pressure jet grouting had to be prevented from causing strata disturbance that affected the safety of the existing pipeline.Also, the construction of the caisson had to be prevented from being blocked after the cement was solidified.

After evaluation, it was decided to use localized close-packed micro-piles for the shaft excavation area and for the surroundings; comprehensive FLW cement chemical grout (SSA+Cement) site improvement method to protect the safety of the existing cable tunnels.

―

3. Works Design

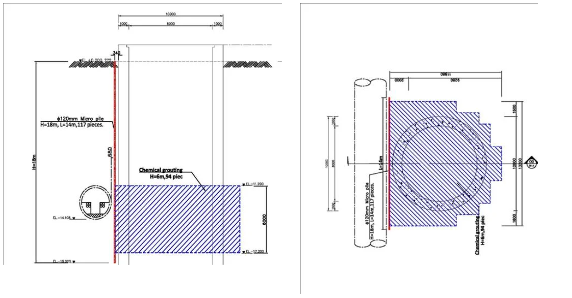

The diameter of the MEA cable tunnel to be protected by this project was about 3.0m, the lower edge of the tunnel was GL-14.6m, and the surrounding soil was a soft clay layer.The protective micro-pile uses a cement mortar pile with a diameter of 150mm and a penetration depth of 18m.

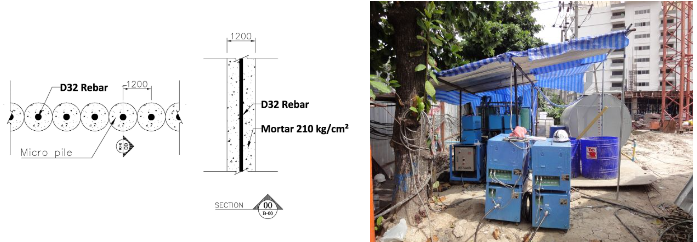

The built-in D32 steel reinforcement was a one-way close-packed design. The distributed length was 14m and the center position was set in the center of the cable tunnel and the vertical shaft.

The soil reinforcement grouting to use FLW cement chemical mortar for compressive splitting grouting to increase the strength of the weak clay layer.

The pouring depth is GL-12.7m~18.7m; the width was 13m, and the site improvement range extended from the side of the micro-pile about 12m, distributed in a checkerboard pattern. The back 1/3 of the extension section to use a stepped reduction design to help owner save engineering costs.

―

4. Works Process

As the shallow pipelines on the surface of this project were relatively simple, the site area was originally a predetermined site for the vertical shaft, and the work site and equipment sites were easy to set up. Everything went smoothly.

After the grout infusion was completed, an on-site permeation test of the improved area was carried out in accordance with the contract.The test results all meet the design requirement of permeability coefficient (k)<10-5cm/sec.

―

5. Results

After the grouting work was carried out according to the design, the vertical shaft caisson operation was started.

During the construction process, monitoring of surface subsidence and deformation in the tunnel showed that the deformation of the MEA cable tunnel under protection was less than the designed safe deformation.

The construction of the vertical shaft caisson and the improvement of the protection site adjacent to the existing tunnel were successfully completed.

PROTECTION OF VERTICAL SHAFT CAISSON CONSTRUCTION ADJACENT TO UNDERGROUND TUNNEL

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd