Underground Culvert Subsidence and Dislocation Repair

UNDERGROUND CULVERT SUBSIDENCE AND DISLOCATION REPAIR Grouting and structural reconstruction technology for underground pipeline 1. Project Background An underground drainage culvert near the MRT caused the dislocation of a pipeline interface due to soil subsidence and other natural events. The severely displaced section was about 10m long and consisted of four 2.5m long D1800RCP pipes.

Reinforcement Treatment of Under-Construction Tunnel Collapse

REINFORCEMENT TREATMENT OF UNDER-CONSTRUCTION TUNNEL COLLAPSE Tunnel collapse and water inrush grouting reinforcement technology 1. Project Background During the excavation of a mountain tunnel, a fracture zone was encountered above the arch line of the workface. Rockslide, collapse and water inrush occurred. The partially completed sidewall supports were deformed by the incursion. Stepwise excavation operation

TBM Launch Site Geological Improvement by High Pressure Jet Piles

TBM LAUNCH SITE SITE GEOLOGICAL IMPROVEMENT BY HIGH PRESSURE JET PILES Geological improvement technology of TBM launch/arrival sites 1. Project Background A large drainage tunnel in a metropolitan area with an outer diameter of 6.0m was constructed using the TBM method. One of the pumping stations was constructed with a work-shaft with an outer diameter

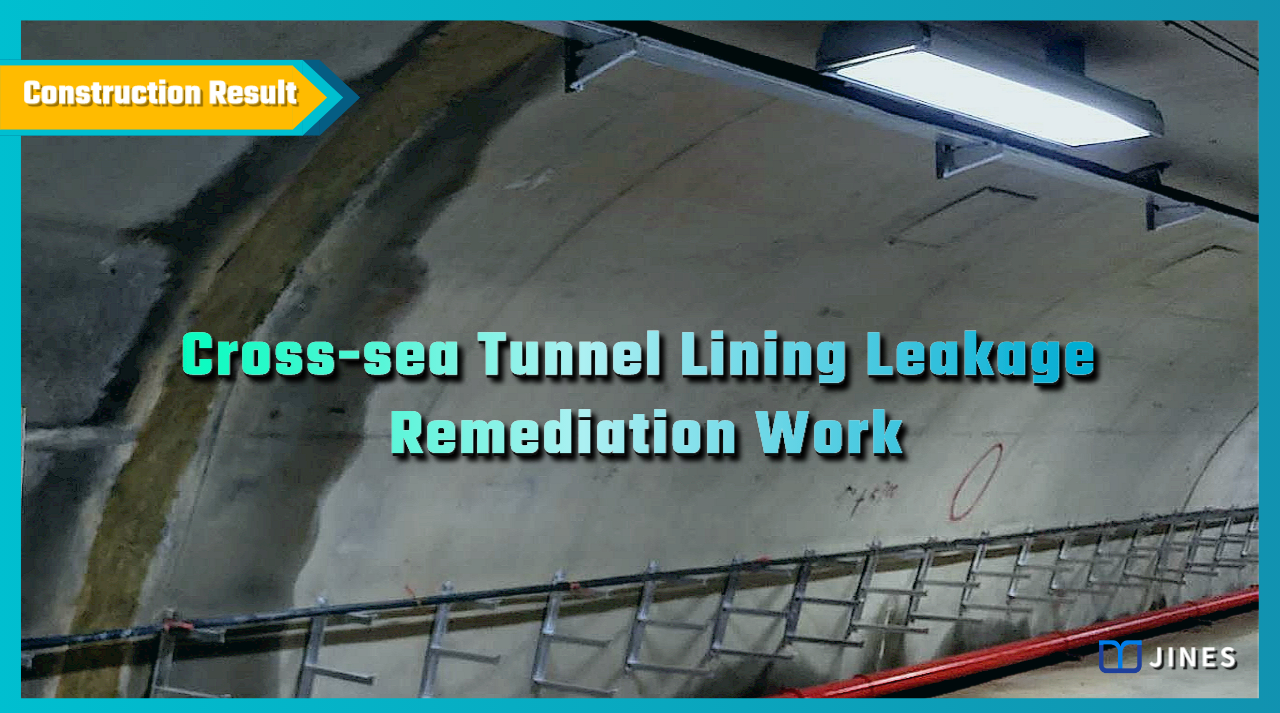

Cross-sea Tunnel Lining Leakage Remediation Work

CROSS-SEA TUNNEL LINING LEAKAGE REMEDIATION WORK Construction joints, honeycombs and faulty concrete leakage and repair case. 1. Project Background A cross-sea tunnel in South China was constructed using the undercut method. After the tunnel lining was poured and the formwork was removed, it was found that there was leakage at annular construction joints, concrete spalling

Jacking Reinforcement and Steel Mill Vehicle Driveway Subsidence

JACKING REINFORCEMENT AND STEEL MILL VEHICLE DRIVEWAY SUBSIDENCE Shallow strata resin grout jacking technology 1. Project Background The driveway outside a steel mill was composed of coarse and medium sand with gravel and silty fine sand with organic matter. Due to the long-term pressure by heavy trucks, differential settlement and localized cracking of the rigid

Deep Foundation Excavation Water Inrush Low-Pressure Grout Sealing

DEEP FOUNDATION EXCAVATION WATER INRUSH LOW-PRESSURE GROUTING SEALING Dual-Pipe Grouting Method Inrush Water sealing technology 1. Project Background The foundation excavation depth of a civil building was GL-23.25m, and the top-down excavation method was being used for the works. When the building was being excavated close to the bottom of the foundation, four water inrushes

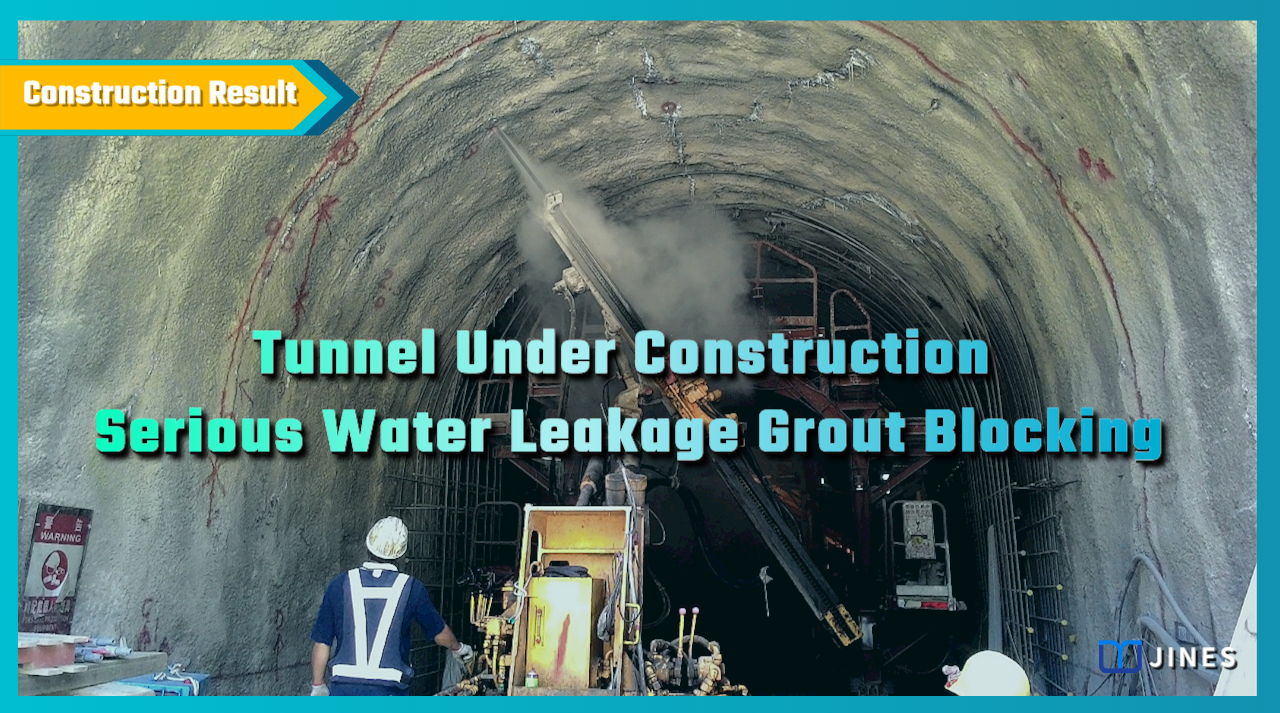

Tunnel Under Construction Serious Water Leakage Grout Blocking

TUNNEL UNDER CONSTRUCTION SERIOUS WATER LEAKAGE GROUT BLOCKING-SELF Expanding polyurethane resin water-stop grouting technology 1. Project Background The surrounding geological conditions of a vehicular mountain tunnel were broken quartz sandstone and slate. Although there were rock strata and colluvium-based alluvial layers with a thickness of about 60m in the upper part, due to broken rock

Cofferdam Waterstop Compound Grouting Technology

COFFERDAM WATERSTOP COMPOUND GROUTING TECHNOLOGY Grouting to prevent water leakage into bridge foundation retaining cofferdam under construction 1. Project Background A new bridge pier was designed with a long-span pile-raft foundation, and the foundation footing was set at a depth of about GL-21.0m below the water surface. In order to facilitate the excavation and construction,

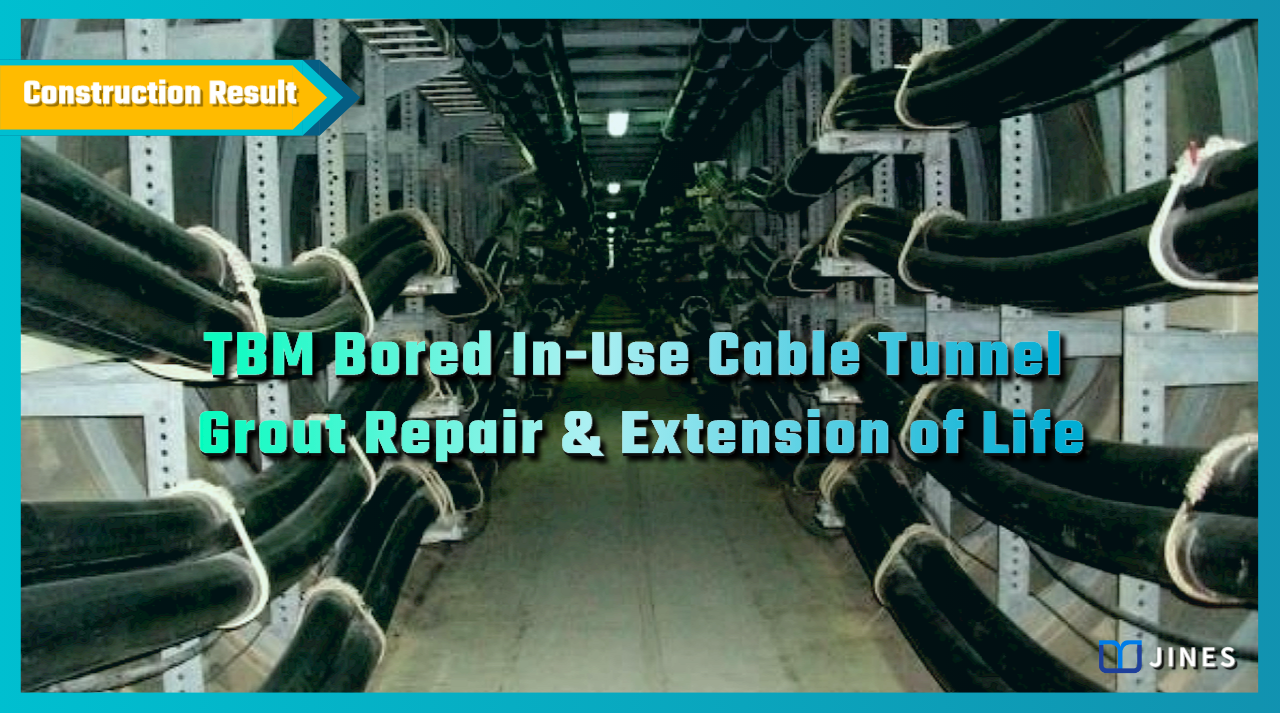

TBM Bored In-Use Cable Tunnel Grout Repair & Extension of Life

TBM BORED IN-USE CABLE TUNNEL GROUT REPAIR &EXTENSION OF LIFE Water-stop reinforcement technology for TBM bored cable tunnel 1.Project Background A cable tunnel in use was constructed using the TBM method. After a period of use, water leakage of various amounts occurred in wells, corridors, linings, flexible joints, ring segments and inverts.The pre-designed guttering in

Preventive Grouting Reinforcement for Industrial Plant Foundations Hollowing

PREVENTIVE GROUTING REINFORCEMENT FOR INDUSTRIAL PLANT FOUNDATIONS HOLLOWING Instant-setting resin grout filling and compression ground improvemen 1. Project Background Preventive Grouting : Yellow-brown and reddish-brown silty clay mixed with sandy silt was the strata beneath the foundations of an industrial plant. After a period of use, it was suspected that foundation hollowing had occurred. After