High-Pressure Injection Grouting Method

1. High-Pressure Injection Grouting : Clarifying the Concept High-Pressure Injection Grouting Method: CCP – Small-Diameter High-Pressure Injection Pile (with Cement Slurry or Small Amount of Additives) Commonly used for: Assisting in water sealing of retaining structures (double-row design on the water-facing side/sand or interlayer formation considerations for effectiveness and verticality/counteracting soil pressures on retaining structures)

Sealing Technology for Foundation Pit Excavation In Sedimentary Strata

SEALING TECHNOLOGY FOR FOUNDATION PIT EXCAVATION IN SEDIMENTARY STRATA Rescue method for sealing foundation pit bottom after large water inrush emergency. 1. Project Background A 10m-diameter shaft was being excavated by TBM for high-voltage underground cable on the Chidlom Station Outgoing Cable Tunnel Project in Bangkok, Thailand. A sudden emergency occurred when the clay layer

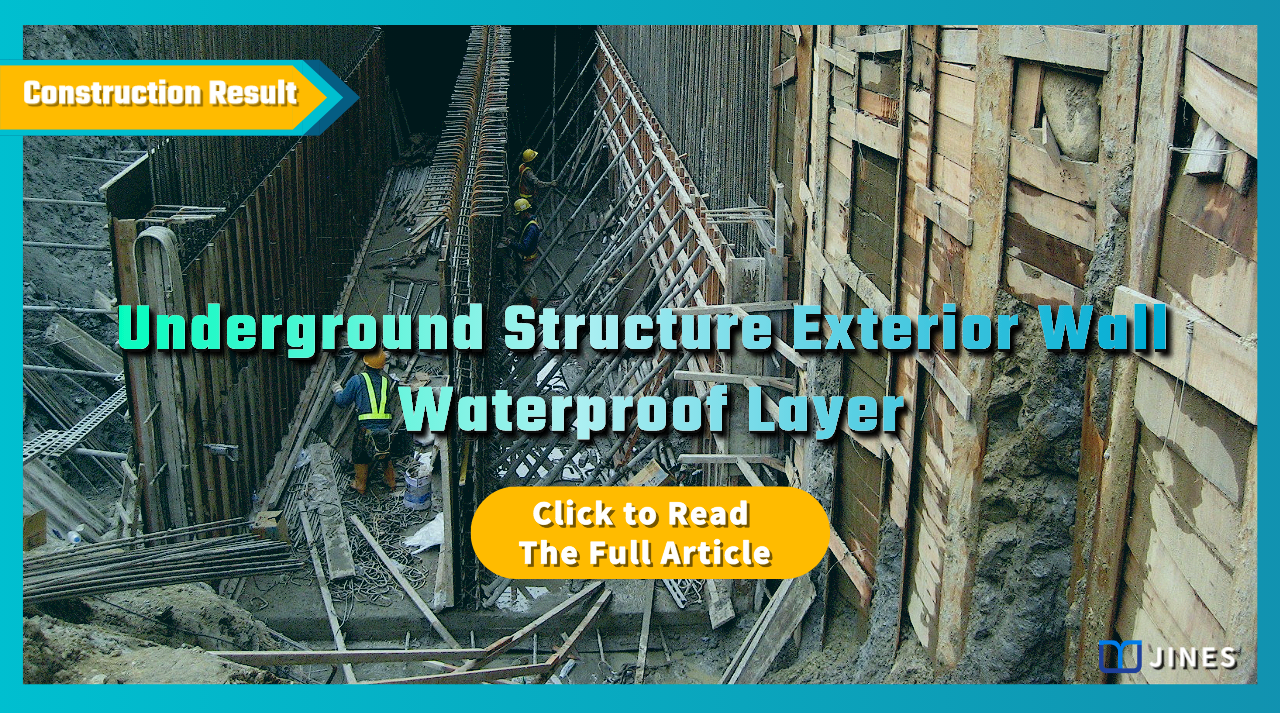

Underground Structure Exterior Wall Waterproof Layer

UNDERGROUND STRUCTURE EXTERIOR WALL WATERPROOF LAYER Hot bitumen grouting technology to form a waterproof layer 1. Project Background A shared pipeline project was constructed by the open cut method. One of the sections could not meet the safety slope requirements for excavation because the adjacent buildings on both sides were close to the excavation surface.

Introduction to Rigid Foundation Precision Jacking Application

INTRODUCTION TO RIGID FOUNDATION PRECISION JACKING APPLICATION Micro-drilling grouting and monitoring technology 1. Project Background For rigid foundations such as rigid roadbeds of expressways, airport taxiways, MRT system track slabs, precision workshop foundations, etc., once the stratum below the foundation is disturbed, subsidence of different scales may occur. After subsidence occurs, the behavior of the

Leakage Reduction Grouting During TBM Tunnel Construction

LEAKAGE REDUCTION GROUTING DURING TBM TUNNEL CONSTRUCTION. TBM tunneling complex leakage reduction grouting technology 1. Project Background After commencing TBM tunneling construction, there were many different forms of water seepage. The water seepage conditions did not meet the criteria required per the contract. In order to improve the construction quality and make the follow-up acceptance

Sealing and Consolidation Grouting of Colluvial Strata at Tunnel Exit

SEALING AND CONSOLIDATION GROUTING OF COLLUVIAL STRATA AT TUNNEL EXIT Exit Dual-tube double-packer grouting reinforcement technology for colluvial rock layer 1. Project Background At the exit of a tunnel was a thick layer of colluvial rock. In order to avoid continuous rock slides on the upper slope during excavation, it was planned to first carry

Pipe Roof Resin Grouting for Tunnel Excavation

PIPE ROOF RESIN GROUTING FOR TUNNEL EXCAVATION Rapid pre-Support pipe roof grouting reinforcement technology 1. Prokect Background At a tunnel entrance there was a poorly cemented colluvial rock block layer about 27m long. In order to prevent the damage of rock collapse during excavation and improve the progress of the project, the construction unit planned

Tunnel Auxiliary Safety Passage Seepage Reduction Grouting

TUNNEL AUXILIARY SAFETY PASSAGE SEEPAGE REDUCTION GROUTING Composite grouting and seepage reduction technology for highly permeable rock formations 1 Project Background During the construction of a tunnel’s auxiliary safety evacuation passageway, water seepage was observed in the arch roof and side walls over a distance of approximately 310 meters. The geology of this section was

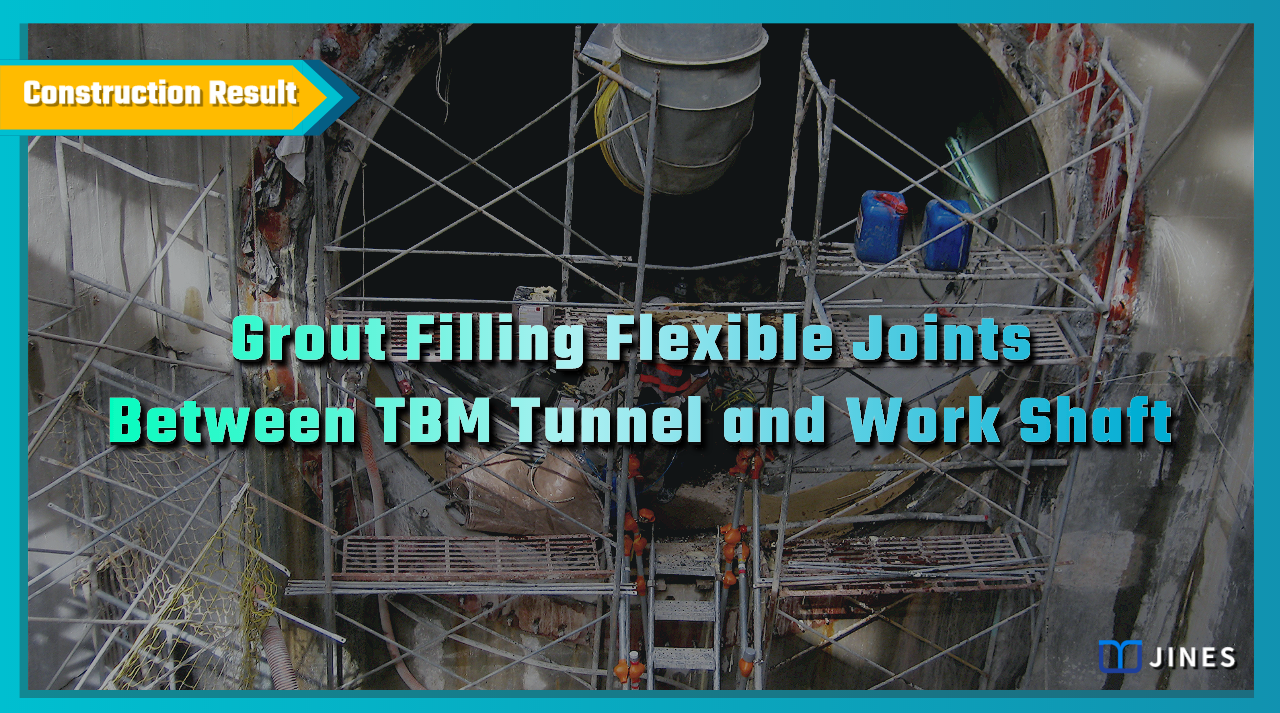

Grout Filling Flexible Joints Between TBM Tunnel and Work Shaft

GROUT FILLING FLEXIBLE JOINTS BETWEEN TBM TUNNEL AND WORK SHAFT Void filling and plugging technology between tunnel structure interface and adjacent strata 1. Project Background Grout : A tunnel had been constructed using TBM method. In order to buffer the interaction between the work shaft and TBM tunnel interface when earthquakes occur and relative creep

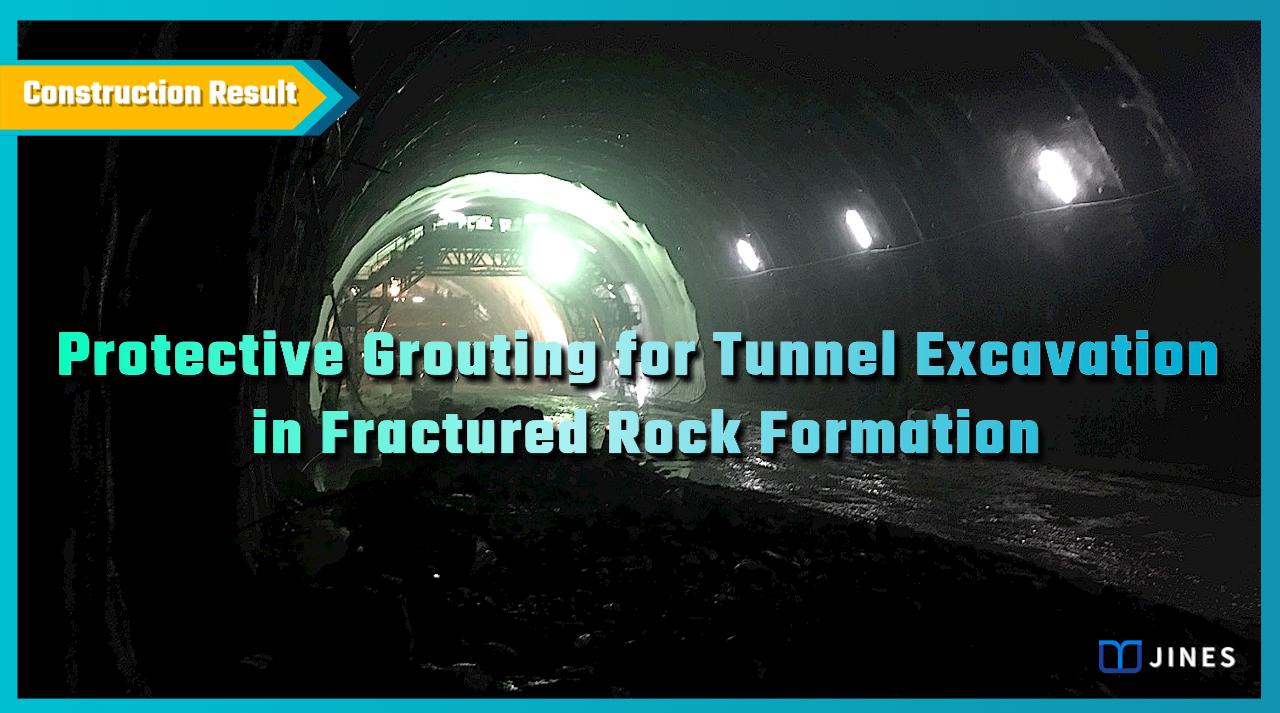

Protective Grouting for Tunnel Excavation in Fractured Rock Formation

PROTECTIVE GROUTING FOR TUNNEL EXCAVATION IN FRACTURED ROCK FORMATION Pre-construction pipe-roof support grouting reinforcement 1. Project Background A tunnel was being excavated by drilling, blasting and mechanical excavation. A section of the tunnel passed through fractured rock formations with underground water veins about 62m long. To prevent collapse, water inrush, rockslide and excessive over-excavation during