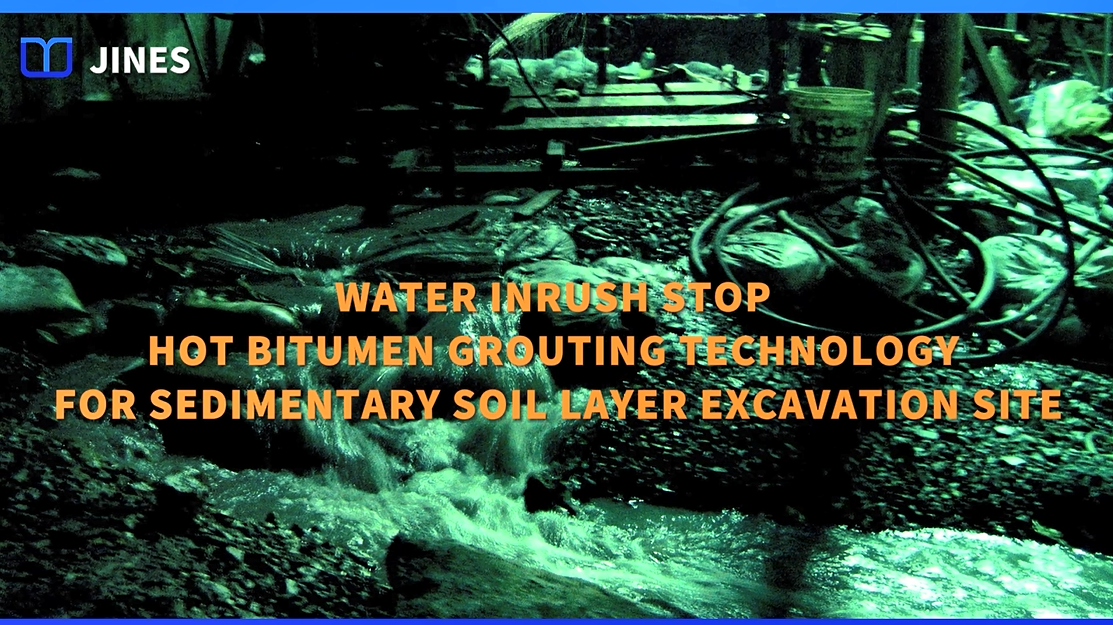

【Video】Water Inrush Stop Hot Bitumen Grouting Technology for Sedimentary Soil Layer Excavation Site

「The site is adjacent to the MRT main line and elevated roads, and it was being constructed by the Top-Down method, with 6 basements. When excavating the basement floor 4 during construction, an unknown buried pipe that was incompletely blocked in the base was encountered, resulting in serious water inrush at the excavation site …

Basics of Grouting

When we mention “grouting,” do you think of it in the context of building houses? Or perhaps using grout material for reinforcement when there’s a leak inside a building? In reality, grouting is a specialized skill, applicable in large infrastructure such as subways, tunnels, airports, and reservoirs. It’s particularly useful when dealing with water ingress

Repair of Basement Floor Water Leakage in Slab Foundation

REPAIR OF BASEMENT FLOOR WATER LEAKAGE IN SLAB FOUNDATION Elastic epoxy polyimide resin grout material for sealing water leakage ― 1. Project Background A community building underwent a comprehensive excavation to establish connectivity within the basement area. The building’s foundation utilized a combination of slab and raft designs. After a period of time, there was

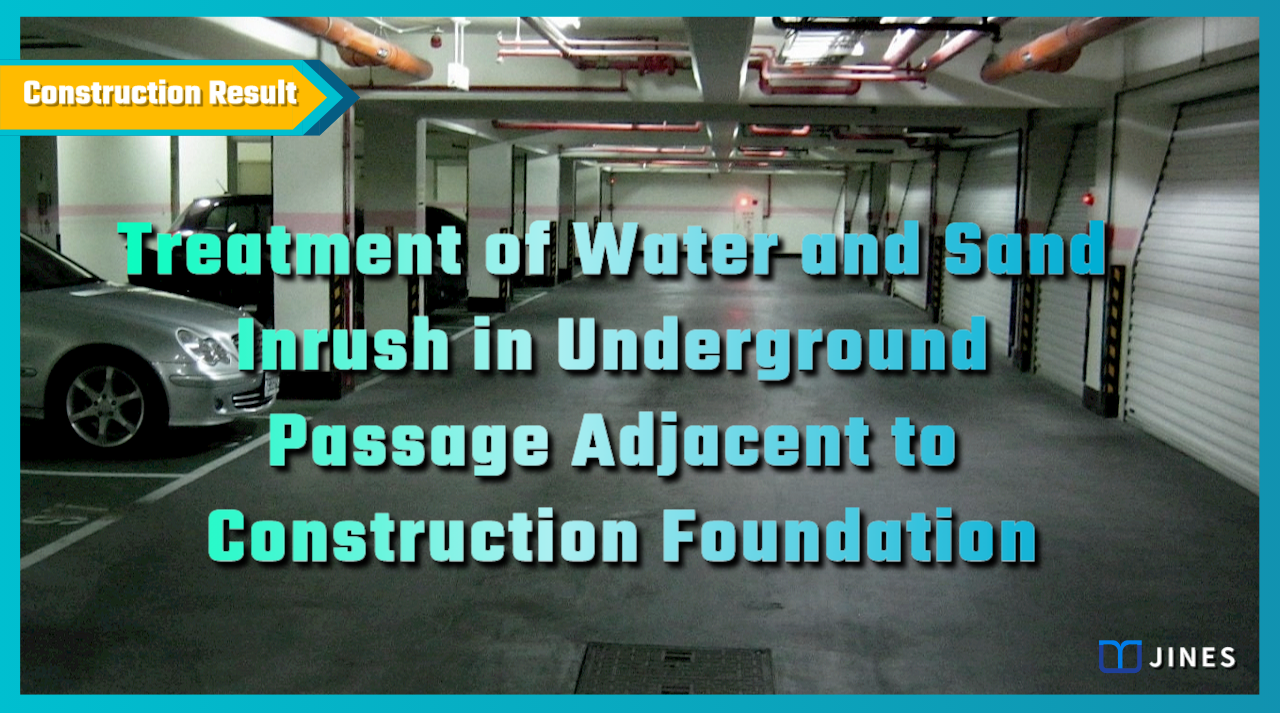

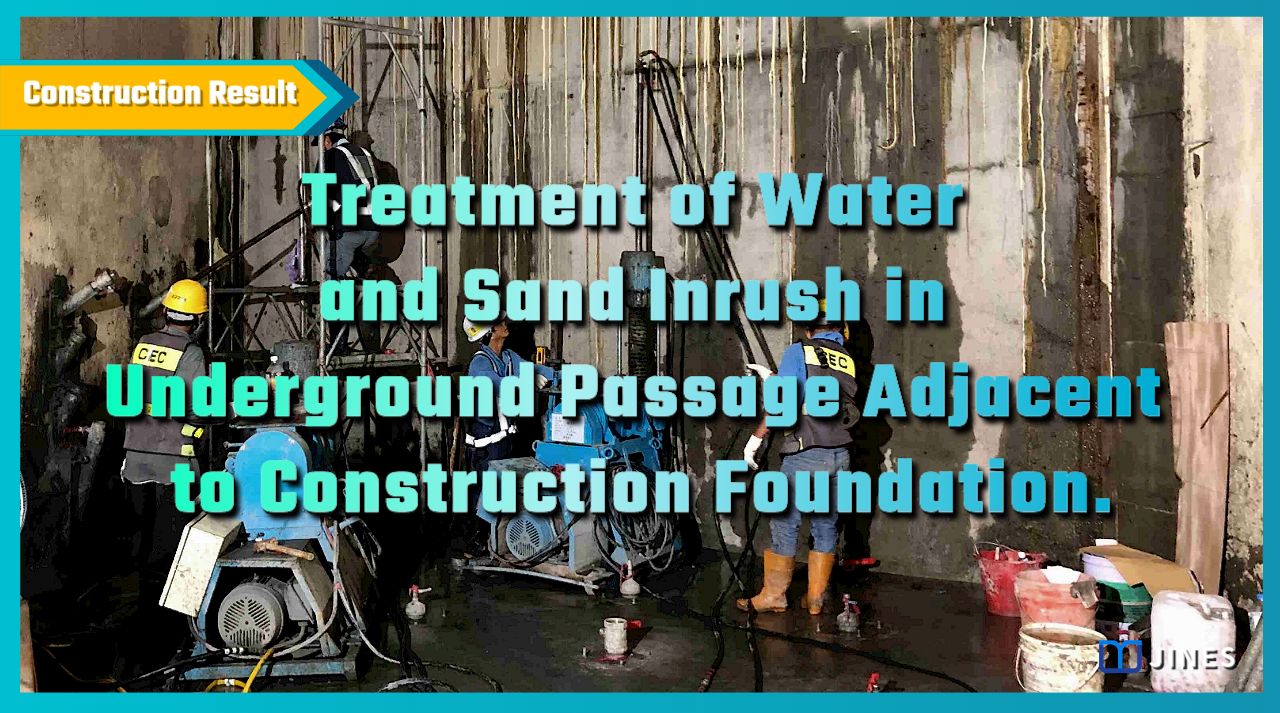

Treatment of Water and Sand Inrush in Underground Passage Adjacent to Construction Foundation.

TREATMENT OF WATER AND SAND INRUSH IN UNDERGROUND PASSAGE ADJACENT TO CONSTRUCTION FOUNDATION Dual-Pipe Technique Combined with Rapid and Slow-Setting Grouts for Water Inrush Sealing ― 1. Project Background In an underground passage near a foundation under construction, during the excavation of a diaphragm wall guide trench, an unexpected loss of stabilizing fluid occurred. This

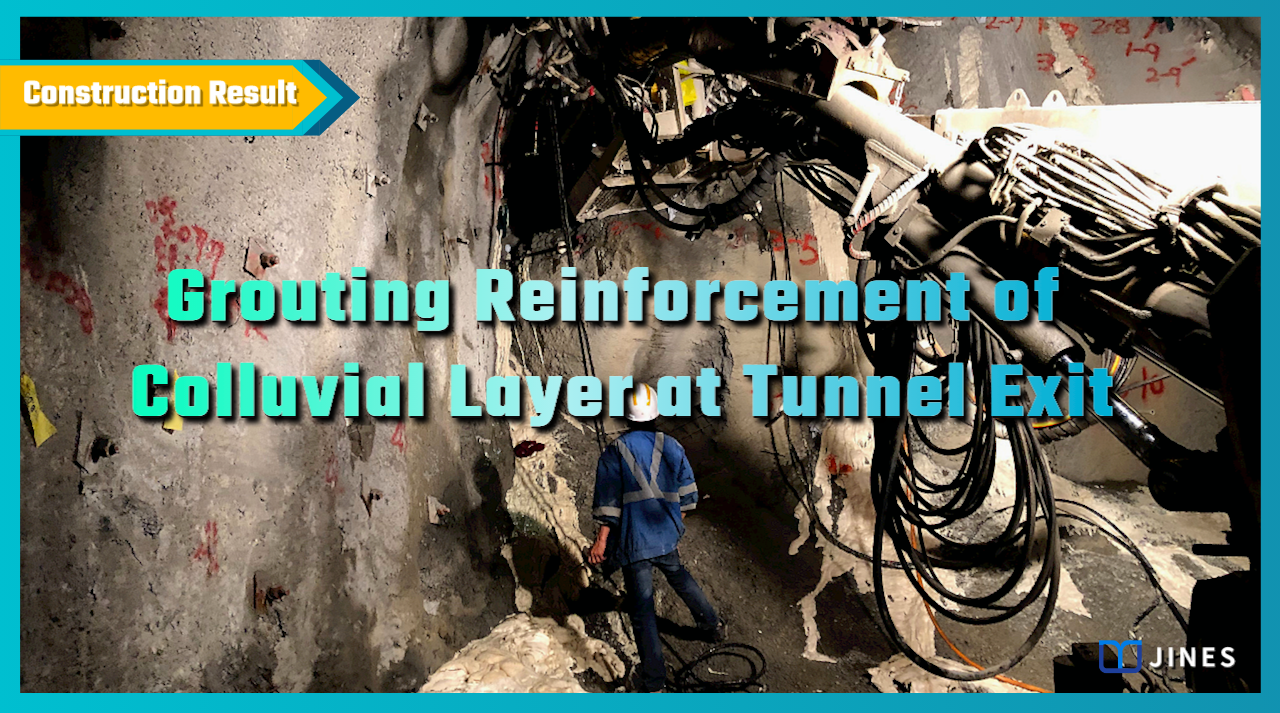

Grouting Reinforcement of Colluvial Layer at Tunnel Exit

GROUTING REINFORCEMENT OF COLLUVIAL LAYER AT TUNNEL EXIT Case study of self-drilling hollow rock bolt grouting reinforcement ― 1. Project Background Above a newly constructed highway tunnel, an exhaust/smoke vent tunnel was installed within a cavity. Due to the steep terrain at the tunnel exit location, external level excavation was not feasible. When the flue

Base Level Grout Sealing of Deep Excavation in Coastal Tidal Zone

BASE LEVEL GROUT SEALING OF DEEP EXCAVATION IN COASTAL TIDAL ZONE Water-stop grouting site improvement technology for base level excavation in saline-alkali area — 1. Project Background A proposed ecological landscape-based seawater supply system was planned to be constructed in a coastal tidal zone. It involved the construction of work shafts and diversion channels. However,

Site Improvement of Technical Backfill Area Adjacent to Bridge Abutments

SITE IMPROVEMENT OF TECHNICAL BACKFILL AREA ADJACENT TO BRIDGE ABUTMENTS Double-packer grouting for homogenization of porous granular backfill and load-bearing capacity enhancement — 1. Project Background In order to ensure long-term operational safety of a light rail bridge abutment, the technical backfill area at the approach section was to be filled with graded gravel. However,

Water Inrush Treatment and Ground Improvement at Thailand MRT Station Excavation

WATER INRUSH TREATMENT AND GROUND IMPROVEMENT AT THAILAND MRT STATION EXCAVATION Water-stop and stabilization improvement of site damaged by ground uplifting 1. Project Background In a Thai MRT station construction project, the reverse construction method was employed, with diaphragm walls penetrating into the clay layer below the excavation level to prevent groundwater infiltration. However, an

Abnormal Machine Vibration: Reinforcement of Industrial Factory Foundation

ABNORMAL MACHINE VIBRATION: REINFORCEMENT OF INDUSTRIAL FACTORY FOUNDATION Ground improvement by loose zone fill and weak zone compaction grouting in soft soil site 1. Background An industrial plant experienced abnormal vibrations in some of its machines after a period of operation. In order to prevent disasters, the management decided to commission a professional firm to

Ground Improvement at Launching Site of TBM Tunnel in Composite Strata

Ground Improvement at Launching Site of TBM Tunnel in Composite Strata Integrated Ground Improvement using Full-Length Casing Piles, High-Pressure Jet Grouting, and Double-Packer Grout Injection 1. Project Background The launching site of an underground TBM tunnel was located at a depth of GL-35.1m to GL-40.2m below the ground surface. The upper part of the tunnel