ABNORMAL MACHINE VIBRATION: REINFORCEMENT OF INDUSTRIAL FACTORY FOUNDATION

Ground improvement by loose zone fill and weak zone compaction grouting in soft soil site

1. Background

An industrial plant experienced abnormal vibrations in some of its machines after a period of operation.

In order to prevent disasters, the management decided to commission a professional firm to conduct non-destructive testing of the factory’s foundation subgrade.

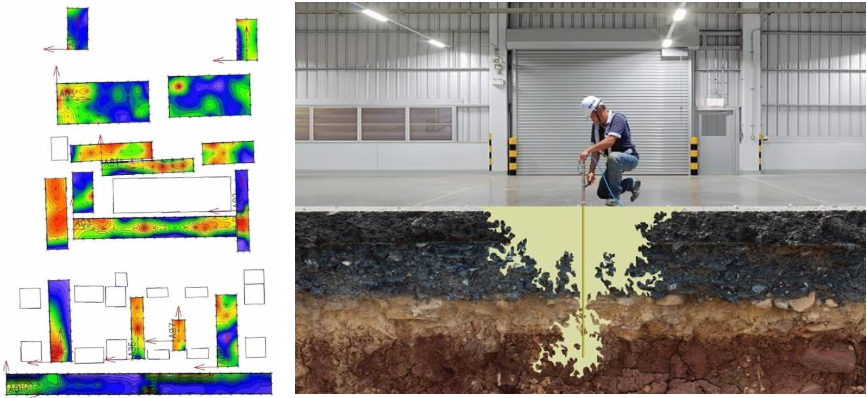

The testing revealed several suspected loose zones and weak areas in the backfilled layer below.

To avoid sudden settlement or rupture of the foundation, which could lead to production downtime and safety hazards, a professional contractor was hired to improve the subsoil below the foundation to ensure long-term operational safety.

—

2. Solution

Based on research and analysis, the abnormal machine vibrations may have been be caused by factors such as surface water infiltration, mechanical vibrations, and subsidence of the original soil layer beneath the backfill layer.

These factors resulted in localized soil softening, anisotropic compaction, and small-scale hollowing, leading to uneven transmission of the upper load to the underlying formation.

Due to limited working space inside the factory, it was not possible to conduct geological survey drilling. To ascertain the inference results, the Dynamic Penetrative Measurement method (DPM), which has minimal impact, was used to detect the position of the formation defect identified in the previous non-destructive inspection in situ and define its range and depth.

Based on the DPM test results, the loose zones below the base plate of the plant were mostly found within 0.0m to 0.8m below the base plate, some between 0.8m to 2.0m, and a few weak zones appeared between 2.0m to 3.0m.

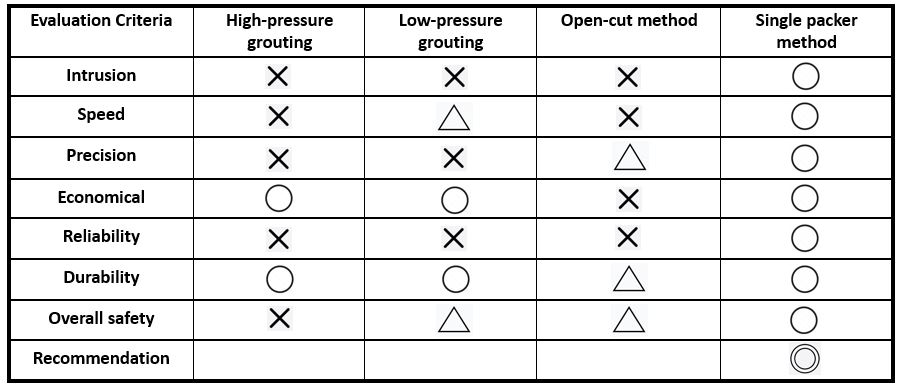

Considering the limited space for large-scale machinery operations inside the factory and the requirement to ensure uninterrupted production, the Shallow Resin Grouting method suitable for ground improvement within 5 meters below the surface was selected.

This method involved filling the loose areas and reinforcing the weak zones.

—

3. Work Design

Due to the limited working space, the requirement to avoid contamination of the factory, the need for rapid improvement results, and the avoidance of excessive damage to the base plate, the construction design included specific measures.

These measures included the use of a rebar detector during layout to avoid the base plate’s reinforcement and the adoption of a micro resin grouting method with small 15mm diameter boreholes set at different angles.

Additionally, the Tipor series of dual-component polyurethane resin grout was employed for ground improvement and filling in the loose areas.

Despite being slightly more expensive, this resin offered rapid curing time, high compressive strength, high flexural strength, non-toxicity, and resistance to degradation and decomposition.

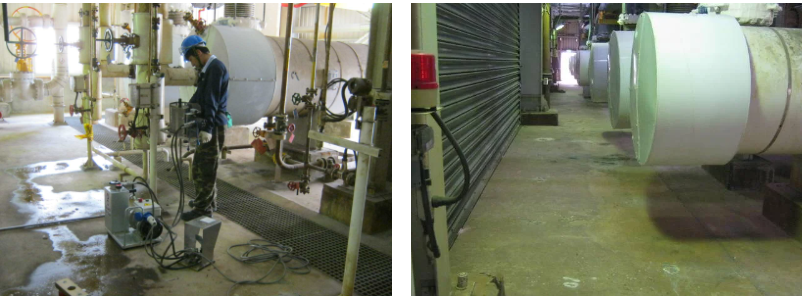

The grouting holes placement was primarily focused on the peripheral aisles around the machines.

By utilizing straight holes and angled holes in the grouting design, the goal of reinforcing the subgrade beneath and around the machines could be achieved without interrupting equipment production.

—

4. WORKS PROCESS

To thoroughly reinforce the subgrade below the factory’s base plate, it was important to address the partially continuous weak zones identified during the previous non-destructive testing.

During the ground improvement process, control was based on the deformation of the floor and the amount of grouting, with real-time monitoring using high-precision automated laser levels.

The slightly higher viscosity polyurethane resin grout was used to ensure that it adequately diffused and filled the subgrade without causing uplift or deformation of the base plate.

This approach aimed to achieve a compaction grouting effect, where the subgrade was properly compacted and the grout enhanced its load-bearing capacity, providing sufficient stiffness to withstand potential machine vibrations.

As there were no signs of settlement or cracking in the base plate prior to the grouting, there was no need for floor jacking. Therefore, during the construction process, the floor jacking height had to be controlled to within 1.0mm.

—

5. RESULTS

After the injection of the designed depth and quantity of grout into the base plate of the factory, the vibration of the operating machines significantly decreased below the standard level.

After a curing period of 48 hours, a follow-up DPM dynamic penetration test was conducted, which indicated that the load-bearing capacity of the subgrade exceeded the design requirements.

Following inspection and verification by the management, the ground improvement results met the expected requirements.

After site cleaning and filling of the grouting holes, the goal of reinforcing the foundation and addressing the abnormal machine vibration issue had been successfully achieved.

—

Abnormal Machine Vibration: Reinforcement of Industrial Factory Foundation

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd