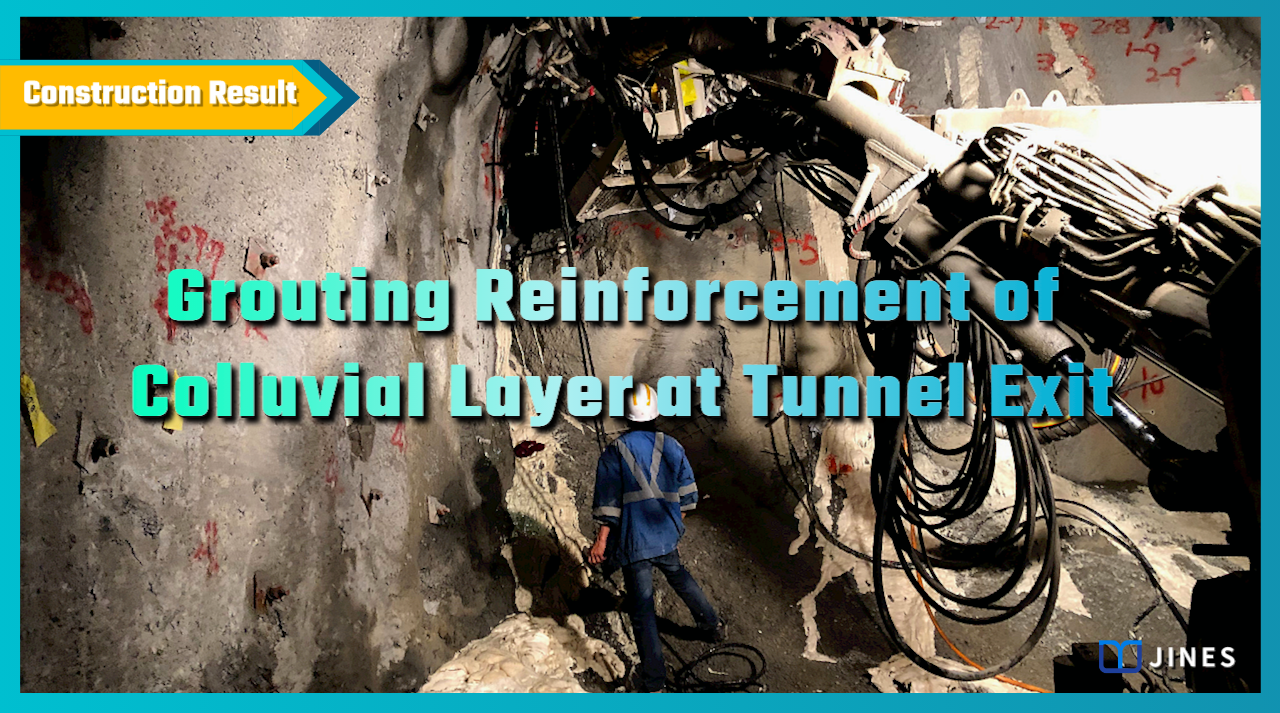

GROUTING REINFORCEMENT OF COLLUVIAL LAYER AT TUNNEL EXIT

Case study of self-drilling hollow rock bolt grouting reinforcement

―

1. Project Background

Above a newly constructed highway tunnel, an exhaust/smoke vent tunnel was installed within a cavity. Due to the steep terrain at the tunnel exit location, external level excavation was not feasible.

When the flue exhaust duct was excavated from the interior to the vicinity of the cavity entrance, due to the shallow-buried colluvial blocks layer loose structure, localized collapses occurred.

The construction team promptly responded by conducting emergency grout spraying and subsequently installing protective mesh on the exterior. They gathered experts from various fields to collaboratively devise a mitigation plan.

A contractor with similar project experience was commissioned to execute a plan.

―

2. Solution

The geological strata at the smoke vent tunnel exit consisted of loose colluvial rock debris interspersed with weathered rock fragments and miscellaneous soil. Attempting to clear this from the slope surface hurriedly could have potentially triggered a chain reaction of slope collapses.

Following a professional assessment, the decision was made to utilize internal grouting to stabilize the collapsed layers around the tunnel exit and then proceed with manual excavation using machinery to penetrate the tunnel exit.

The objectives of the implemented solution were as follows:

(1) Stabilize the collapsed layers outside the excavation line of the smoke vent exit section;

(2) Reinforce the surrounding rock layers of the excavation pit mouth with a circular array of inclined grout injections;

(3) Consolidate the excavated rock surfaces;

(4) Minimize construction duration and mitigate the impact on project progress.

―

3. Works Design

Based on the on-site survey, it was found that the colluvial rock layer at the tunnel entrance possessed porous and low cohesion characteristics, making traditional cement-based and chemical-based grouting materials unsuitable.

After careful evaluation by experts from various fields, the decision was made to use Tipor-03, a non-solvent polyurethane resin with high adhesiveness, short curing time, high strength, and micro-expansion properties, for colluvial layer infusion.

During construction, a percussion drilling rig was used for the installation of self-drilling hollow rock bolts.

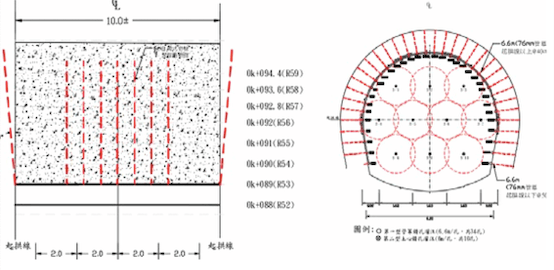

The hollow rock bolts were arranged in three sets as follows:

(1) Outside the excavation line, holes were to be drilled starting from the arch line at a spacing of 3 meters per hole, with drilling angles ranging from 15 to 20 degrees outside the excavation line.

(2) Outside the excavation line, holes were to be drilled starting from the arch line at a spacing of 6 meters per hole, with drilling angles ranging from 10 to 15 degrees outside the excavation line.

(3) At the excavation face, holes were to be drilled at a spacing of 6 meters per hole, with drilling angles perpendicular to the excavation face, forming a radial angle of 90 degrees.

Each round of grouting to be executed using the Split Method to achieve comprehensive grouting confinement.

Grouting to be conducted from both sides towards the center top arch. The sequence of grouting for each hole could be adjusted according to on-site conditions as needed.

―

4. Works Process

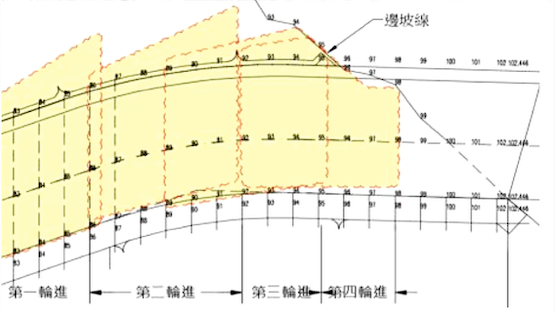

The localized ground improvement work employed support pipe roof in combination with Tipor-03 polyurethane resin for circular grouting design. This was carried out in accordance with the tunnel exit excavation depth, and a total of 4 rounds of grouting operations were executed.

To minimize project delays and reduce the risk of tunnel and slope collapses, each round of ground improvement was required to be completed within 48 hours. The goal was to promptly utilize the bonding properties and strength of the improvement grout, enabling the immediate commencement of the next phase of work.

In order to meet design requirements, the setting time of Tipor-03 polyurethane resin grout material was controlled to be within 1 minute. The grouting equipment utilized a high-output pneumatic grouting machine in conjunction with an automatic control recorder to achieve a thorough grouting effect.

―

5. Results

Since there was no significant groundwater inflow in the pores of the colluvial rock layer, the grouting process primarily focused on cementing the rock fragments and filling the voids.

Through sequential grouting to stabilize the exterior excavation zone and single-level grouting for the excavation face, the colluvial layer’s self-support and cohesion were effectively enhanced within a short period.

This successful reinforcement, in conjunction with the client’s objectives, facilitated the completion of the tunnel breakthrough operation, successfully achieving the task of grouting reinforcement for the colluvial layer at the tunnel exit.

―

Grouting Reinforcement of Colluvial Layer at Tunnel Exit

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355