HANDLING OF DAMAGED UNDERGROUND TUNNELS

Techniques for structural repair and leak prevention in underground conduits

―

1. Project Background

After a period of usage, a functioning underground tunnel and its connecting access routes had experienced various issues due to factors such as natural disasters, changes in geological conditions, and aging. These issues included surface lining cracking and peeling, concrete cracking and water seepage, aging of joint sealing materials leading to water infiltration, and localized water inrush through cavities. In order to maintain the functionality of these structures and ensure the safety of inspection personnel, the operating authority commissioned a professional contractor to conduct on-site surveys, document the types of damages, their locations, and quantities, and propose repair solutions for implementation.

―

2. Solution

Based on the results of the on-site survey, the underground tunnel damages could be broadly categorized into five types, which were as follows:

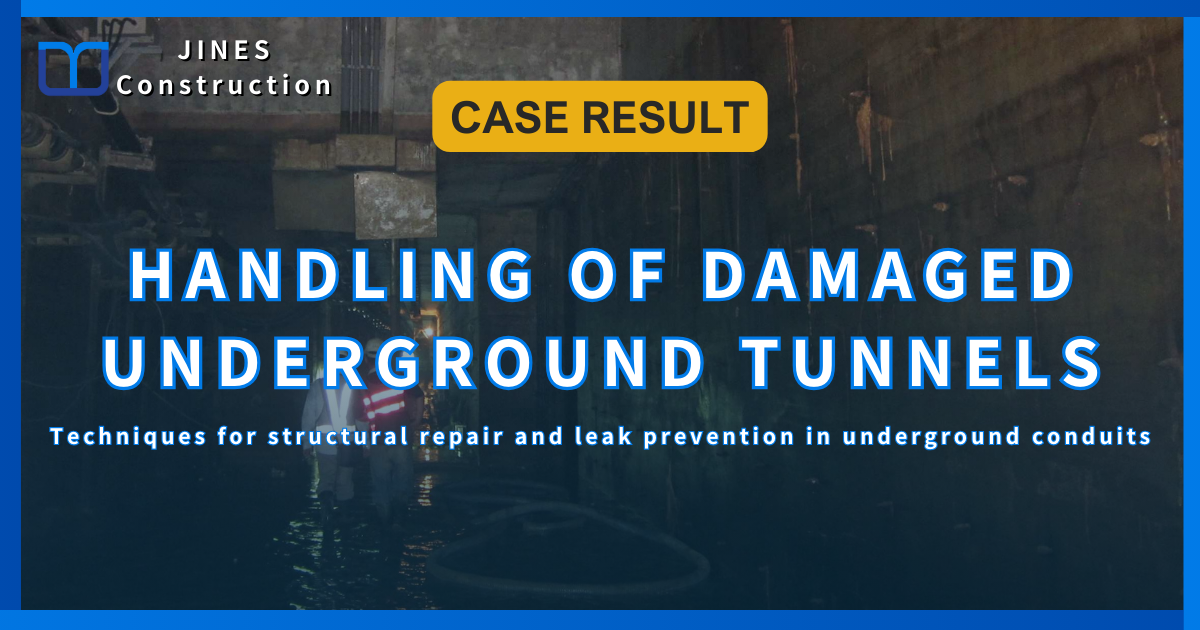

(1) Repair of water-seepage-related cracks in the tunnel lining;

(2) Repair of water seepage through holes in the tunnel lining;

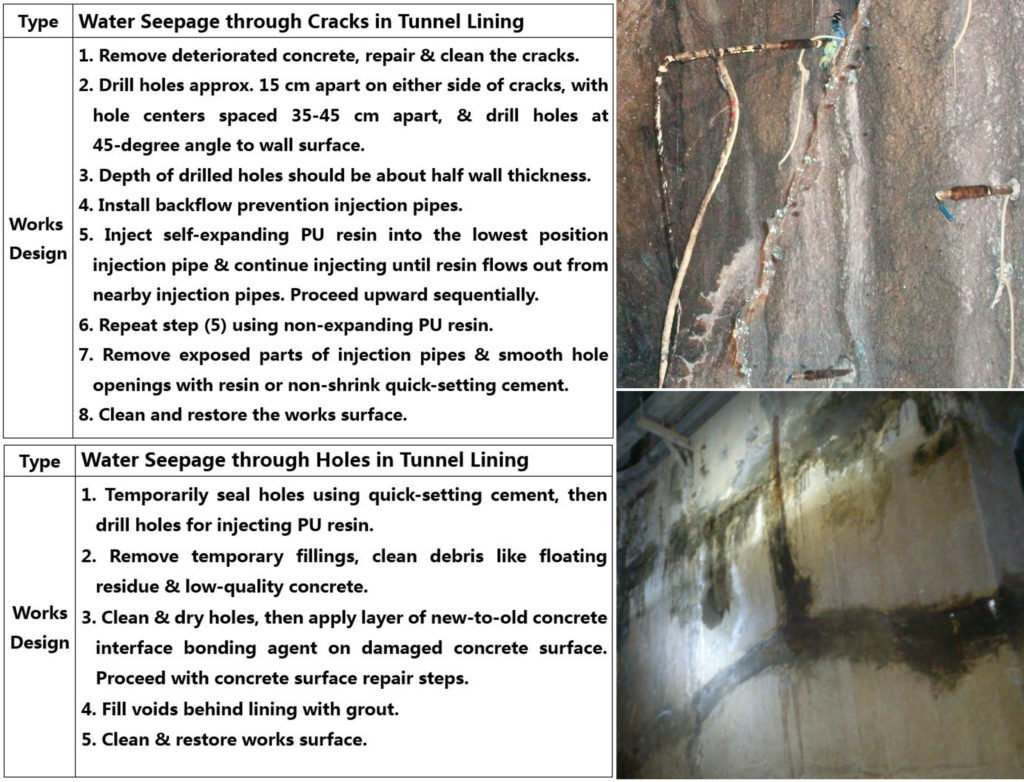

(3) Repair of joint sealing materials in the tunnel’s concrete;

(4) Repair of the surface of the tunnel lining concrete;

(5) Protection of the surface of the tunnel lining concrete.

Due to the different characteristics and treatment methods for each type of issue, when formulating solutions, various techniques such as high-pressure water cleaning, grouting, sealing, spraying, adhesion, and plastering were to be applied as needed for their respective management.

―

3. Works Design

―

4. Works Process & Results

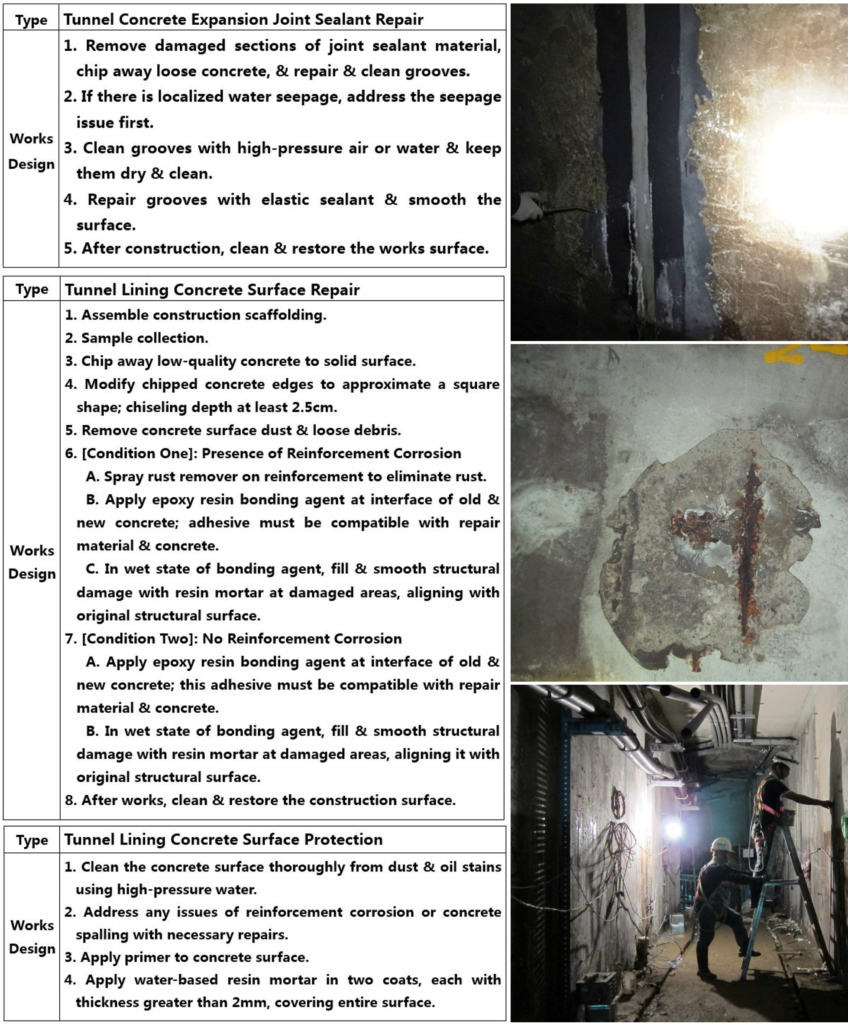

Before commencing the remediation of the underground tunnel, there was a presence of stagnant water, silt accumulation, and deteriorated concrete detachment. Prior to construction, preparations involved ventilation, dewatering, removal of debris within the tunnel, and cleaning the work area.

Given the substantial length of the underground tunnel, it was divided into sections based on the elevation of the tunnel floor. Submersible pumps were placed at the lowest points in each section, and equipment installation, piping layout, and water and silt removal were carried out through nearby ventilation shafts. Most of the operations were scheduled during off-peak traffic times and at night to minimize disruption to urban traffic.

Following the sequenced execution of the construction design, the repair efforts were highly effective. Although the damaged underground tunnel could not achieve completely dry conditions, the original design’s drainage system and ventilation equipment were used to restore the tunnel to its original design functionality, ensuring the safety of routine operations.

After inspection by the operating authority, the requirements of the contract were met, successfully completing the remediation of the damaged underground tunnel. To prevent future damage to the tunnel, the operating authority also signed a maintenance contract to promptly address any potential hazards that may arise in the future.

―

・More Construction Result Sharing

Contact us:+886 2769-2355