UNDERGROUND STRUCTURE EXTERIOR WALL WATERPROOF LAYER

Hot bitumen grouting technology to form a waterproof layer

1. Project Background

A shared pipeline project was constructed by the open cut method. One of the sections could not meet the safety slope requirements for excavation because the adjacent buildings on both sides were close to the excavation surface.

In addition, there was a continuous layer of pebbles and gravels under the surface of this section, so the construction unit made a change and used steel piles with main pile horizontal slats for soil retaining excavation, and poured the side walls of underground pipes in a single-sided modular way.

This construction method could not be applied to the waterproofing of the side wall facing the water, so after changing the design, it was decided to use hot bitumen waterproofing layer injection moulding technology for the waterproofing of the exterior wall.

―

2. Solution

In order to align with the nature of this project and construct a complete side wall bitumen waterproof layer, the solution was formulated as follows:

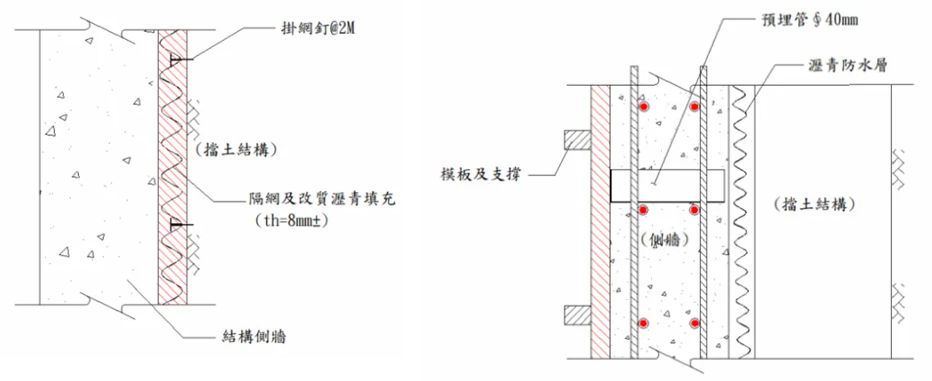

(1) Reserve a space between the main pile horizontal slats and the reinforced concrete with a thickness not less than the original design waterproof felt;

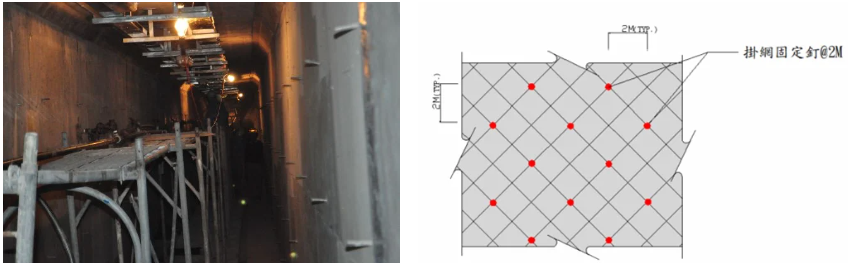

(2) Lay grids and waterproof layers for the flow and distribution of hot bitumen in the space;

(3) Embed grouting pipes and vents;

(4) On-site construction of hot bitumen spread range monitoring system;

(5) The selected bitumen material must have good cohesiveness, fluidity at high temperature and elasticity after curing.

―

3. Works Design

According to the conditions listed in the solution, the works design was as follows:

(1) Install plywood on the inner side of the main pile horizontal slat as the outer mold of the waterproof layer

(2) lay a hollow grid and waterproof layer with a thickness of about 8mm

(3) Arrange the grouting pipes so they do not penetrate the concrete protective layer of the side wall in a staggered manner @400mm when binding the side wall reinforcement

(4) Use separate hot bitumen grouting equipment for pouring

(5) Use the embedded thermocouple temperature sensor checkerboard configuration, install it on the outside of the side wall, and use the automatic capture system to monitor the hot bitumen spreading position in real time

(6) Use modified bitumen as the grouting material, and use 180-200 degrees Celsius as the working temperature, and 90 degrees Celsius as the lower limit for the heat pump to start.

―

4. Works Process

After allowing time for concrete pouring, maintenance and membrane removal, the construction unit first used polyurethane resin grouting to seal the defects where the side wall concrete might have caused grout loss.

Large-scale equipment such as hot bitumen heating tanks and heat pumps were hoisted on the ground surface, and then thermal insulation pipes were connected to the near end of the predetermined grouting position.

When grouting, pour was in the order of from bottom to top, and the grouting hole above was used as the exhaust and overflow hole.

If there was a location that could not show uniform temperature rise during thermocouple monitoring, drilling and hot bitumen refilling would be carried out in that area.

―

5. Results

Because the surface of the horizontal slats of the main pile was not smooth, the plywood after being laid underwent localized deformation when subjected to hot pouring pressure, resulting in the amount of bitumen being greater than the design value, and local surface grout overflow occurred.

After adopting the second-degree grouting and cooling-down slowing-down grouting method to strain, the monitoring results showed that the hot bitumen had filled the gap between the side wall and the earth-retaining facilities.

After a long period of observation, the poured hot bitumen waterproof layer was used at the construction site, and no water leakage occurred.

―

Underground Structure Exterior Wall Waterproof Layer

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd